|

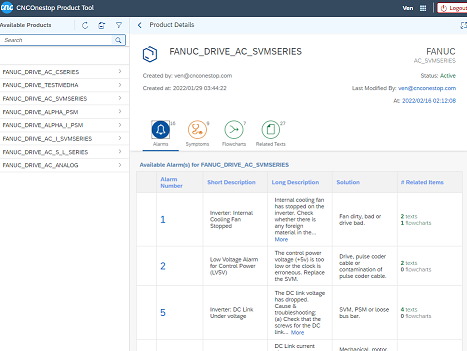

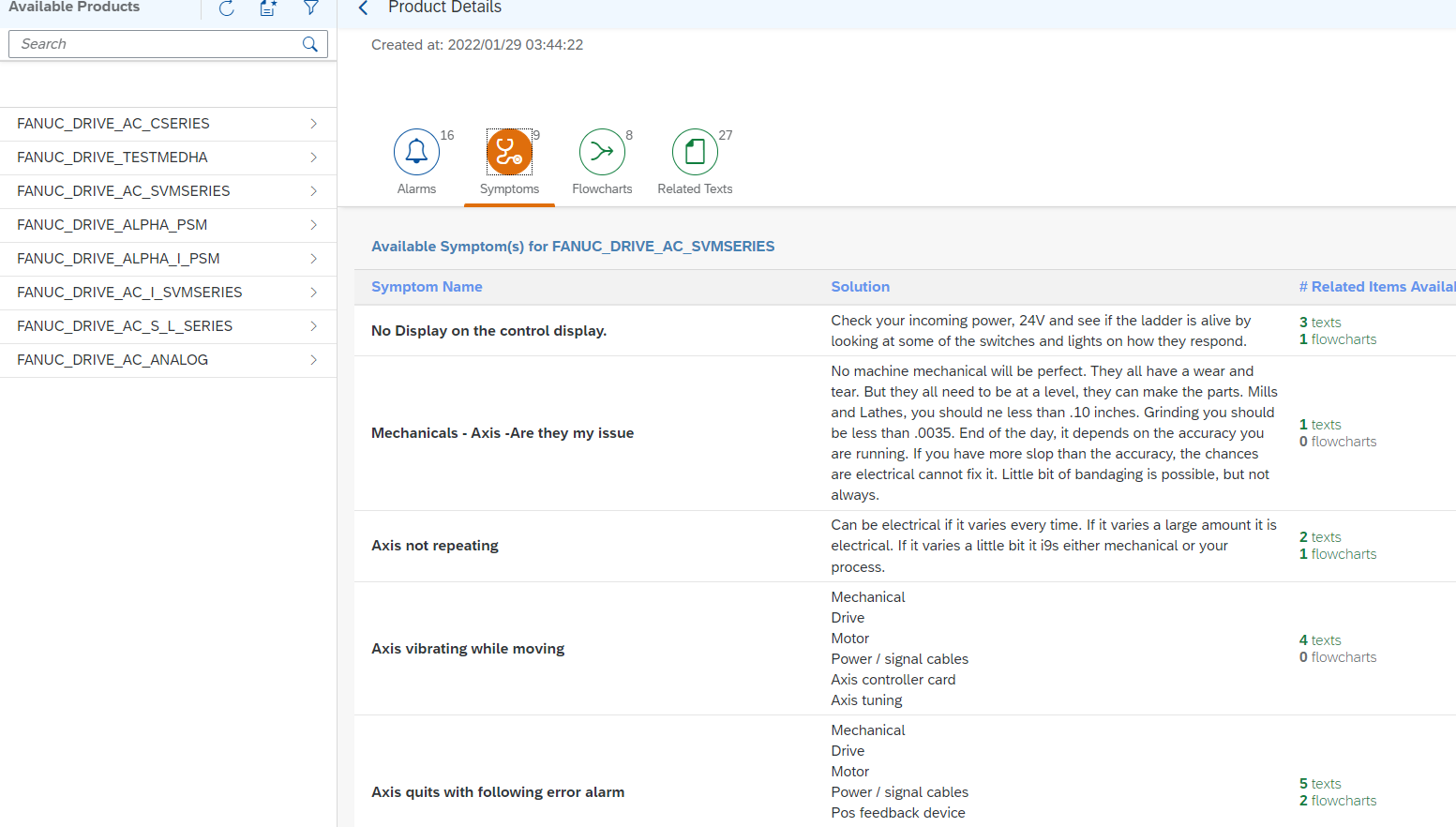

50% of the problems are servo problems. Any

one can troubleshoot with basic knowledge.

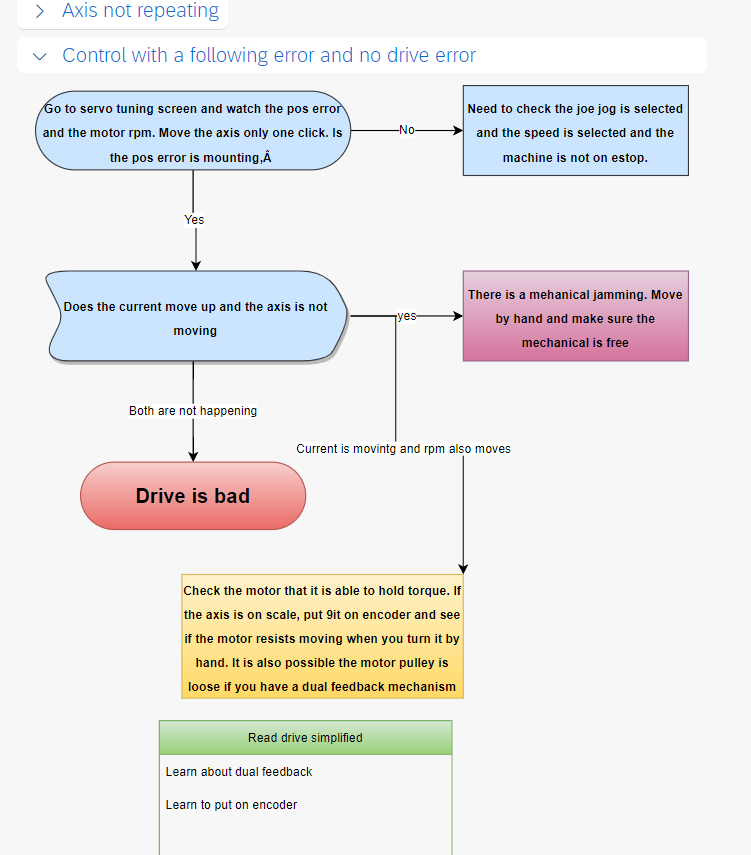

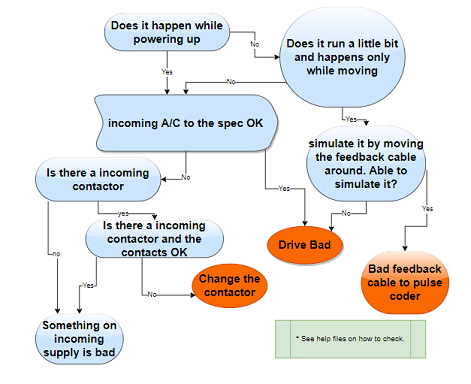

Flowchart with simple YES or NO questions.

Text and picture help to answer the

questions.

You can save 1000s. PERIOD. Premium members get email and phone

support for free.

FANUC

Drive troubleshooting and CNC

troubleshooting- Android-

Free Download

FANUC

Drive troubleshooting and CNC

troubleshooting - Apple IOS-

Free Download

How to select an Alarm and Symptom

Description

This is the go to app to learn the

fundamentals of CNC Machines.

Do you know that

it costs an average of $5,000 for a service

engineer to walk into your facility? Using

this troubleshooting app you can learn how the

machine and its components work.

The Step by step

flowcharts included in these two apps will

walk you through to troubleshoot your

problem. All you have to do is answer YES or

NO. If you don’t know the answer, you have

help in the form text that can help you

answer the question. The idea is to narrow

it down to one or two faulty parts.

Sometimes buying two parts is cheaper and

faster than getting a CNC engineer to visit

your site.

We have alarm and

symptom approaches to troubleshooting.

How to

get more info on other products

Visit

www.drmachines.com to learn about

what is done so far and what else is on the

pipeline.

Collaboration and customization

Who

are we:

This

is a troubleshooting knowledgebase app is

brought to you by CNC Onestop, Inc. who are

experts on all kinds of CNC and PLC based

machines. We also sell parts and we have

special offers, free tech support and free

restocking privileges for those who buy

parts from us. We also give training to

people in your location or in our location.

History:

Our

Chief Engineer Ven Swaminathan has a Masters

degree in Electronics and has over 35 years

of 15 hour a day hands on service

experience. Even today he is much sought

after in almost all of the aircraft and

automotive companies in the US. He

personally has worked for 1200 companies in

North America. He is experience in more

than 100 type of controls and a few hundred

models of machines. His passion towards

bringing his knowledge to the machine tool

owners to do it themselves has evolved into

the tool called Share Your Expertise.

Plans: We

are launching the first version of this app

for free. We will be adding more makes and

models of drives, spindles and controls. We

also provide help through Apple FaceTime for

a fee. We also have support engineers who

can come to your place and troubleshoot your

machine. We are all about quality and

one-stop troubleshooting. There are no

machines we cannot fix. When we walk out we

will have your machines running. We provide

the parts you need and will be one-stop

solution for you. Either do it yourselves or

take our help to the extent you like. We

want to be the one-stop center for your CNC

needs.

Partners: We

are also looking for independent service

engineers all over North America. If you are

an independent service engineer and if you

have what it takes to troubleshoot any

machine send us your resume. If you meet

our expectations, you will have an

opportunity to represent us. Our engineers

work about 3000 hours and wait time is 3

weeks to get one. We have contract with

several OEMS to service their machines all

over North America. Our average is one out

of 50 people who apply qualify to work with

us. We are for quality than quantity. We

look for technical ability, attitude to

troubleshoot, maturity to deal with the

customer and above all a CAN DO attitude. If

you are the best in the business, email us.

Visit

www.drmachines.com to learn about

what is done so far and what else is on the

pipeline. If you need a portal for your

company and any more ideas you have on how

you can use the system inbternally.

SAMPLE OF KNOWLEDGEBASE FROM THE APP

Knowledgebase on CNC

4. Different parts of a CNC Control

4.1

Numerical control:

Photocell was used to

detect the holes punched in a paper tape. NC

control used this information and sent a

command to the servo drives to make the

move. This is how simple the NC machine was

in the earlier stages of 1960s.

4.2

CNC Control:

After the development

of computers, which comprised of memory,

input/output mechanism, display unit and a

keyboard, it was possible to create, edit

and delete a program with ease. Combining

the computers to NC machines made it a CNC

machine. The following topics will deal with

different components of a CNC machine.

4.3 Power supply is

the heart of a machine. Without a power

supply nothing will work. A power supply

gives out DC voltages for ac input. There

are different kinds of power supplies. The

common one is Linear.

4.3.1 Linear Power supply:

This is a basic power supply. For an ac

input it gives out specified dc output. Even

without a load it will put out an output. It

regulates the output voltage up to a

designed load. Some power supplies will blow

a fuse if it is overloaded and some will go

into a fold back mode putting no output but

still saving the power supply. The

efficiency is low. It is bulky. The main

characteristic in service point of view is,

it should put out a voltage with no load. It

can have several protective circuits.

4.3.2 Switching Power

supply (SMPS): Switching

mode power supplies are advanced power

supplies. The efficiency is high. With

higher loads it goes into protective mode.

This makes it more reliable and gives a

longer life span. It is also possible to

design for varied inputs like 100 to 240

volt input for the same output. It is

compact and can weigh very less. Most of the

laptops has this kind of power supplies.

It has to be tested with the

minimum specified load. Though some of them

will put out voltage without a load

connected to it, the earlier models will

need a load to be connected to it.

4.3.3 Checking of Power

Supply:

a) Machine may have more than one power

supply. One for the control, one or more for

drives one for spindle, one for external

source (Mostly 24V). First thing to find out

which power supply is being suspected.

b) Make sure the input ac is available

at the terminal of the power supply to the

specification. Always measure across the ac

terminal than going across terminal to

ground.

c) Check all the possible dc outputs.

Dc output should be 1.414 times the A/c

input. Be aware the PSU may have its own

transformer inside to supply different AC

inputs for several possible DC outputs.

d) Check the dc outputs with no load or

slight load

e) If there are some extra wires other

than input they could be acting as switch

from external sources. Make sure they are at

where they should be.

f) Remove all the loads and check for

resistance across the wires like 5V and 0,

12V and 0, 24V and 0. Make sure they are not

shorted, by measuring the resistance across

the load. If they have very low resistance

or short, then the problem is in the load

side and not in the power section.

g) Once it is decided, it is the power

supply, check for any blown fuses in Input

or Output side.

h) Remove all the wires and check for

the Input resistance on the power supply and

whether it is shorted.

i) Similar to the above check and

make sure the Output resistance of the power

supply is not shorted either.

j) If you suspect only one power

supply load side is shorted, Load Testing

can be done. Calculate the power output by

multiplying output voltage by rated current,

and find a bulb with lower than that

wattage. Connect it and see if it comes on.

A thing to remember is, if it is a switching

PS all the outputs should have a minimum

load.

k) Some power supplies might have a

terminal for Remote Sensing. This senses the

voltage at a remote place where the load is

and adjusts the power supply to put out a

voltage specified at the remote place. A 5V

PS can be 5.2 at the output terminals, where

as it could only be 5V at the remote place.

l) Some power supplies may have a

capacitor externally connected. Make sure it

is OK.

4.4 Power Conductors:

The wires, which are carrying the power

supply to different section, have to tight with least amount of drop in the

wires as well as in the connectors. Otherwise will behave unpredictably.

4.5 Processor:

Processor is the brain of a CNC machine.

When this is dead it is like; the machine is in coma. It can not apply

logic. Normally the processor board can be one or more than one boards,

depending on when it was made. It takes the information from the memory,

processes it, and gives the appropriate command to the axis and spindle.

While doing so it takes input from the input board as to what is the status

of the machine like whether it is in home or not, has it been homed yet,

what is the position of the tool changer etc. Then it processes that

information through logic called "ladder" and decides whether it can ask the

Axis to move, so that it will be a safe movement. Also it gives output to

tool changer, pallet changer, based on the present status of the machine.

Usually processor boards will have some

light indicating that it is running or halted. This gives a good indication

about whether it is having a problem or running OK. Lot of machines have

motherboard which will have processor board built in with some other

features. It is always advisable to read the specific description about the

processor board. This information can be found in the control manual.

4.6 Memory: I t is same as in human memory. The commonly

used memories are RAM, EEROM/EPROM/Core memory and Hard disk/Bubble memory.

Core memory was used to store all the information. This kind is not being

used because of poor reliability and cost. Most of the recent machines use

EEROM/EPROM for storing the system information, RAM for parameters, and hard

disk for programs.

RAM - Read and write memory, fast access

time

ROM - Read Only memory

EEROM - Electrically erasable ROM

EPROM - Same as above, but can be erased

only under UV rays.

Hard disk/Bubble memory - Can be read and

wrote but not as fast as RAM, but cheaper.

Usually some memory boards have s few

lights indicating whether it is faulty or Ok. Parity alarm is the most

common alarm. If the memory gets corrupted or loses the information often,

is an indication of memory board starting to go bad. It is always a good

practice to have the memory backed up. When this boards goes bad the machine

will look like brain dead. The way to differentiate between the processor

bad or Memory bad is from the lights on the boards. Some controls will put

up the message on the screen if the memory is bad.

4.7 Control Wires:

These are the wires which takes feedback as

to what is status of a machine and feeds it to input board. Also it gives

the command when some movement has to take place. These wires are connected

to Input devices and output devices. If these wires not intact or if they

are not properly grounded, the system will behave inconsistently, and one

will see intermittent faults.

4.8 Input Board:

This is most cases is a separate board

connected to input devices and the processor. This might take 5V, 12V or 24V

based on the make. This board converts the voltage to 5V and sends it to

Processor in a sequential manner. Most of these boards have one led for each

input, which is helpful in troubleshooting.

4.8.1 Input Devices:

The switch comprises of two parts, one is a

switch and the other is a contact. The switch is connected to a contact.

This contact can be normally open (NO), or normally closed (NC). For example

the wires going out of the contact can be connected in such a way, that it

can put out a higher voltage or lower voltage when the switch is actuated.

Pressure switch - Can be set to actuate the

contact when the set pressure is reached.

Limit switch - Can be set at a particular

place, to give a signal that particular object has reached that position

Flow switch - Can be set to actuate the

contact when the set flow is reached.

Float Switch - Can be set to actuate the

contact when the set quantity is reached.

Magnetic reed switch - Same as a limit

switch, but uses magnetic principle instead of physical contact.

Proximity Switch - Proximity switch senses

when an object reaches proximity to the switch. Since it is fully electronic

there is no contact. Instead it has a PNP and NPN model. PNP puts out the

supply voltage as output when a object comes close to it, and NPN sinks the

supply means puts out 0V. Few more things to remember are

a)

Some switches have 3 wires and some has two wires. The extra wire is

common.

b)

Some of them will sense only metal and some a few more metals.

c)

They work under 3 different principles magnetic, inductive and

capacitive

d)

Some can be mounted flush and some cannot be.

e) Some have a led showing the change of status. But in some cases

though the led may seem to work, the voltage may not all the way go to zero

or vice versa. Malfunctioning is common on these switches.

4.9 Output board:

This is normally a

separate board connected

to output devices and the processor. This board receives 5V signal from the

processor in a sequential manner and converts them to. 12V, 24V or 110V AC

based on the make. Most of these boards have an LED for every input, and in

some cases fuses too. This is helpful in troubleshooting. This board may

drive directly drive the output device or it maybe connected to a relay. In

turn relay may be used to drive the output devices.

4.9.1 Output Devices:

Solenoid: Most of the machines have

hydraulics and pneumatics. This is what is used to actuate the auto tool

changer, auto pallet changer etc. Solenoid is the most common form of output

device. They work on 12V and 24V DC, and 110V AC depending on the choice

selected by the OEM.

Light bulbs: Another output device to

indicate the status or alarm.

One speed motor: Coolant motor is an

example.

Bigger contactor: A bigger contactor might

be connected to an output device to actuate a bigger motor like hydraulics

motor.

4.10 Servo Board:

This board is located in the CNC

Controller. This gives command out to the servo drives and takes feedback in

from the positional feedback units. It also performs the same function with

the spindle. In some occasions, if the tool changer motor is configured as a

drive, than it is controlled by this card too.

4.11 Peripheral Board:

This board is part of the CNC control. This

board is used to interface with Keyboard, Monitor and peripheral devices

like Reader, Punch, RS232C etc.

4.12 Peripheral devices:

Peripheral device is used to a) communicate

commands to the processor b) load a series of commands in to the memory and

c) give output from the memory or processor to a CRT or a punching device.

4.12.1 Keyboard:

Every control has some form of

communication to input the commands. Keyboard is one of the commonly used

interfaces. This is connected to the Interface board. If it has more

switches for specific function, than it is connected to the input board.

4.12.2 Monitor:

CRT is the most common form of display unit

used in the machine. This is connected to the peripheral board too. LCD is

widely used because of its compactness.

4.12.3 Paper tape reader:

It is the oldest form of Input device. Though

the technology of reading has changed, functionally it does the same

function of loading.

4.12.3.1 Paper Tape:

Paper tape is nothing but a roll of paper

in which holes are punched. Every character has a set of holes assigned by

ISO or EIA standard. That is what is punched in these tapes. When a paper

tape reader reads this, it writes that alphanumeric character into the

memory, as we would type using a keyboard. It is just faster and more

accurate way loading the information into the memory.

4.12.4 Magnetic tape reader:

This is another device using magnetic tape

instead of paper tape.

4.12.4.1 Magnetic Tape:

This is another method of storing the

information using magnetic principle like any audio or videotape. It has a

longer life and is stronger.

4.12.5 Output Peripheral device:

It is used to punch out the contents of the

memory. Paper tape Punch is the most common form of output device.

4.12.6 Input/Output Peripheral device:

4.12.6.1 RS232C:

This has replaced all the older forms of

slow and expensive devices. Also this can function as input/output device.

All is needed is a computer with a serial port. Also one computer can be

networked to several controls. Involves some setup time.

Though it is simple, it could be tedious to troubleshoot.

Some steps to watch

1)

Baud rate, start bit, stop bit, parity and handshaking are the

important parameters that should be same between the machine and the

computer,

2) The COM port should be set right on the computer. - This can be

confirmed with control panel of window settings.

3) The first character, which each control recognizes, is important.

4) After all this is set the equipment which is going to receive the

file should first be ready. Only after that sending equipment should be

started.

5) After all this if it does not work, get a working computer and make

it work with the machine or take the present computer to a similar machine

and make it work.

6) The board in the control can cause it not to work or the board in the

computer can also cause it not to work. The best way is to swap and find out

where the trouble is.

7) The cable is an important piece of the pie. Make sure the cable works

with some other machine.

4.12.6.2 Floppy Disk:

This is becoming one of the widely used

devices. It is reliable, fast and no setup is needed. The amount of memory

it can hold on a disk is limited.

4.12.6.3 Network Card:

The very latest machines have the

capability to be networked. This is extremely fast.

4.12.6.4 DNC/Drip feed:

This is used in older machine where the

memory was not enough. Mostly this was used in Mold components because the

size of the program. A computer is connected with the machine and it loads

to the extent the CNC can take. It stops when CNC sends a signal to stop and

start loading into the memory.

There are several in between devices

available to do this task. They act like they are tape reader and take the

program from the computer and feed it to the control as it seeks the

information. Care has to be taken to have as much information and manuals as

possible when you buy one of these devices.

4.13 Hand Wheel:

It

is constructed like an encoder. This is

used move the axis in handle mode. It is connected normally into servo board

on the controller side. In the very latest machines this unit's out put is

converted into serial and given to the controller as a serial input.

Scope can be used to check the older ones.

There are two signals out A and B. They are 90 degrees apart. The output is

a square wave with 5v in Magnitude.

4.14 Battery Backup:

Most of the machines have a battery backup

to store the contents of the RAM. As mentioned earlier RAM is used for

storing parameters.

When the battery low alarm occurs, never

shut the machine down. Keep it on and exchange the batteries. The polarity

of the battery cannot be changed. Change all the batteries at once. Keep the

machine on for a while after the battery is changed, so as to let the

battery charge up.

4.15 Executive Tape:

After the evolution of CNC controller

though, all the system information was put into the tape and loaded in.

Whenever the system memory was lost, the entire system has to be loaded

back. The disadvantage was the user could not edit it.

4.16 Parameter Tape:

Later stages when different kinds of more

reliable memories were developed, the system memory was divided into two.

One is secure system, which is stored in the form of EPROM etc. The second

is variable piece of information called parameter was loaded into RAM or EEROM. This was accessible by the user to edit when necessary. When a memory

is lost only the parameters needed to be loaded and not the entire system

memory. This tape is called the parameter tape. Now a days it is uncommon to

find tapes instead they are backed up in the form of disk through RS232.

Knowledgebase

on Drives, Motors and feedback devices

4.17.1 DC

Motor:

DC motor has an armature and a field, wound

over poles (also called stator). The field

can be a permanent magnet or a winding which

needs a power supply. The armature is the

rotor, which is also a winding. Since it is

the central rotary part, a commutator is

needed to transfer the power from outside.

The speed control is achieved by varying the

armature voltage or field voltage (if there

is one). Speed increases when armature

voltage is increased or field voltage is

decreased.

Resistance check: DC motor needs a

lot of maintenance. Since carbon brushes are

used, they wear out and makes the commutator

and the surrounding area dirty. It is good

to take the brushes out and blow out with

dry air, once in 3 months. Also check the

resistance across the armature, and it

should be in single digit. If it is more,

that means the contact between brushes and

commutator is not good. Also check the

resistance between the ground and one

terminal of armature (ground resistance). It

should theoretically be fully open

(Infinity). But it will be Meg ohms. If it

is in kilo ohms, it needs cleaning. In case

of field the resistance is in the range 100

to 700 ohms. This check gives a quick idea

of whether there is problem. But a Meggar

check is the foolproof check for ground

resistance, since it generates about 400V

AC. When doing a Meggar check there is a

chance to damage the circuit to which the

motor is connected. Always disconnect the

motor from rest of the circuit to have a

good reading. There is a good chance

there is more than one motor of the same

kind in the machine. It is always a

good idea to compare it with another good

motor. If necessary the motor could be

switched, to see whether the problem

switches.

Current

Check: Check the current using clamp on

meter and see if it is abnormal compared to

the nameplate specification of the motor. It

is not abnormal for a motor to draw up to 8%

of its rated current, at standstill. Also

check for almost equal current on both

directions of movement (Axis which moves

against gravity will have unequal current).

The axis against the gravity normally draws

more current than the other axes.

Heat check:

If the motor is warm it is OK. If it too

warm or not tolerable by hand-touch, then

there is a problem.

Cable check:

The cable, which carries current to the

armature, should have almost zero drop.

Check for any short of the cable to the

ground.

Not to do:

1) Do not take a hard emery sheet and

clean the commutator. By doing this more

minute pits are made and it makes it worse.

Try always to clean with dry air or alcohol

using a soft cloth.

2) IF YOU ARE SENDING THE MOTOR OUT FOR

REPAIR SEND IT TO PLACE WHERE THEY HAVE A

SOUND KNOWLEDGE OF THE MOTORS. LOT OF PLACES

WILL PUT THE ROTOR IN A LATHE AND TURN THE

COMMUTATOR AND QUITE A FEW TIMES THEY SHORT

THE COMMUTATOR OUT. Lot of them do not

balance these after they do turning. By

sending it to the wrong place you might open

a can of worms. If it is grinding spindle

motor, take extra care in sending it out.

4.17.2 DC

Drives:

DC drive is

the electronic control, which provides

proper power to the motor. It gets a voltage

called command voltage (Normally 0 to +-

10V) from the CNC control. It also gets

feedback from a tach generator, which

measures the present speed of the motor. The

drive adjusts the output voltage based on

the above two voltages. It also has some

enabling signals. The OEM based on their

machine tool design uses these signals.

Command

Wire/Tach wire to the Drives:

The wires

have to be tightly secured, and the ground

wires must be properly connected according

to the design.

4.17.2.1

Troubleshooting sequence for a servo problem

a)

Check whether there is input 3 phase

or 1 phase.

b)

Check for the fuses in the drive on

the power section.

c)

Some machines use a separate 1-phase

ac supply to the control section. Make sure

they are ok

d)

Check all the voltages like 5V, +12V,

-12V are ok on the drive.

e)

Check for enabling signals, if they

are used.

f)

Check and see whether there is some

DC voltage coming in when it is commanded to

move.

g)

Do the Tach-check mentioned in Tach

section.

h)

Do the motor check mentioned in motor

section.

i) Balance adjustment: Make sure the

motor does not move when Command signal is

zero (Put a jumper across the command

voltage, after removing the wires coming

from control).

If it moves adjust the

balance potentiometer to stop the movement.

j) Gain adjustment: If the movement is

rough, or the motor overshoots, or if the

motor vibrates; reduce the gain, by

adjusting the potentiometer on the drive

k) If another axis has a similar drive,

it can be swapped to see whether the problem

switches to the other axis.

4.17.3 AC

Motor:

All the newer machines have AC

motors. Every maintenance person comes

across a question whether the motor is bad

or the drive is bad. How do you tell if the

motor is bad. Can you even tell if the motor

is bad. Absolutely. The following tips will

walk you through in a simple step by step

process.

AC motor is cheaper compared to DC motor and

needs less maintenance. It can be single

phase (2 wires) or three phase (3 or 4

wires) for the armature. It has a solid

rotor unlike DC motor.

Heat check:

When the motor gets hot that is an

indication either the load is high or the

motor is going bad. Heat is generated due to

loss of current inside the motor either by

really working on the load or leaking

inside. First line of check is to measure

the current.

Current Check:

Check the current using clamp on meter. Use

a true RMS clamp on meter. The new

generation of motors will have a high

frequency also on the lines. If the meter is

not a true RMS meter it will give erratic

readings. It is not abnormal for a motor to

draw up to 12% of its rated current (See the

name plate), at standstill or no load. If

the no load current is higher than 25%

further checks are necessary. If the load

current is in the range of 50% and higher

the motor will get hot which is OK.

Resistance check:

Next check is to check the resistance across

armature. Use a Multi meter to check the

resistance. When you check the resistance

make sure the motor is disconnected from the

drive. The resistance should be in single

digits. Bigger the motor the lower the

resistance. It is not unusual for a 50KW

motor to have a .3 ohm resistance. Second

resistance check is to check the resistance

between the ground and one terminal of the

armature. (ground resistance). It should

theoretically be fully open (Infinity). But

it will be Meg ohms. This check gives a

quick idea of whether there is problem.

This means the motor is leaking current to

the ground. The third more thorough check is

to do a Meggar check. You can pump in a

higher voltage into the motor and check

ground resistance. There are several

companies sell Electronic Meggars. When

doing a Meggar check there is a chance to

damage the circuit to which the motor is

connected. Always disconnect the motor from

rest of the circuit to have a good reading.

There is a good chance there is more than

one motor of the same kind in the machine.

It is always a good idea to compare it with

another good motor. Some motor manufacturers

would want the resistance to be in the 200

Mega Ohms. Anything below 10Mega ohms is a

problem.

Cable check:

If the readings are not high with Meggar

check, make sure the cable is disconnected

and the check is performed on the motor

terminals. The cable, which carries current

to the armature, should be completely open

without motor or the drives disconnected to

it. If the resistance is 100 Mega ohms or

less the cable should be replaced.

Mechanical Check:

Make sure the bearing are Ok. The air gap

between the stator and rotor is 1mm. There

cannot be much play in the bearings.

If you decide to send the motor to a shop,

make sure you take readings of ohms before

you send it out and check it when it comes

back in.

4.17.4 AC

Analog drives:

AC drive is

the electronic control, which provides

proper power to the motor. It gets a voltage

called command voltage (Normally 0 to +-

10V) from the CNC control. It also gets

feedback from a taco generator, which

measures the present speed of the motor. The

control adjusts the output voltage based on

the above two voltages. It also has some

enabling signals. The OEM based on their

machine tool design uses these signals.

Command

Wire/Tach wire to the Drives:

The wires

have to be tightly secured, and the ground

wires must be properly connected according

to the design.

4.17.4.2

AC Digital

Drive:

Though the

overall function is the same as analog

drive, none of the signals can directly be

measured. Also none of the pots can be

adjusted. All adjustments are done on the

control in the form of various parameters.

The same tach can be used for positional and

speed feedback.

1) If a drive is suspected just a simple

switch which addresses the drive can be

changed and find out if the problem switches

to another axis.

2) Some drives do have parameters stored

in the drive itself. When a new drive is put

in these have to be loaded; or else the

drive will not function right.

3) In most cases the gain and balance

etc are adjusted in the control.

4) VGN is velocity gain which acts as

gain in analog drive

5)

PGN is positional gain. This comes in

to play when there is a positional problem.

6) The best way to handle this kind of

situation is to have a backup of parameters.

It helps to know the default parameter from

the book.

7) If it is humming, there is a

parameter to suppress a particular

frequency. This will help if the motor is

not really being overloaded.

8) The key is to always look at the load

current. If it is within limits then the

machine is OK.

4.17.5

Feedback

devices: Velocity and

position are two the kinds of feedback.

Velocity is for speed stability and this is

achieved by the drive. Position is for the

accuracy, and is achieved by the CNC

control. Each feedback has few devices,

which are normally used to achieve the

objective. Some of them are analog and some

are digital. The way they are connected will

depend on the objective and the type of

feedback device.

4.17.5.1 Velocity

or speed feedback devices:

Tach - This

is a device which is used to measure the

speed of rotation of the motor. It is a

generator, which puts out voltage based on

the speed of the motor. This could be at the

end of motor shaft, or it can be at the end

of ball screw. It could be directly coupled

or through a timing belt.

DC: This is

exactly like a dc motor, but it generates

voltage.

Check:

Checking a Dc tach is similar to a DC motor.

The resistance across tach terminal is about

150 ohms. The commutator needs periodic

cleaning. The brushes need to be

periodically changed and the spring tension

needs to be checked. Also another check to

perform on the commutator to go segment to

segment and make sure that no two segments

are open. This will cause the speed to

fluctuate and not be steady. If it has a

bearing it needs to be checked too.

AC:

This is

exactly like an AC motor. Could be 1 phase

or 3 Phase.

Check:

The windings can be checked for resistance.

All the three phase should read

approximately same. If it has a bearing it

needs to be checked too.

4.18 Spindle: Spindle is

used to run the tool on part to machine it.

Normally it is the biggest motor on the

machine. Recent machines has AC motors, but

it was more common to see DC motors. The

main reason being is its characteristics to

have high torque at low speed. It is common

to see a Gearbox due to the reason that it

can run at wide range of speed, constant

torque and constant horsepower mode.

4.18.8 Regenerative

braking: When the

spindle is stopped from a high RPM to zero

in a very limited time, the regenerated

electricity by braking is dissipated in the

power resistors. These resistors are big,

and care should be taken in touching it.

4.18.9 Orientation: This is

necessary to make the tool changer work. The

spindle has to come to the same spot every

time when ATC is made to do the tool change.

This is done by a mechanical device, and

some electronics to make it come to the same

spot (could be a Resolver or encoder). This

position can be adjusted by electronics or

parameters based on the type of drive. It is

similar to homing sequence on the axes.

4.18.10 Threading or

non rigid tapping:

Whenever

these features are available in a machine,

that means a Resolver is used to bring it to

the exact position, every time. For more

details check positional feedback devices.

4.19 Positional

Feedback:

Means the

feedback to the control to maintain the

position (In case of digital there could be

just one unit acting as both velocity and

positional- This device could be either

going to the control first and the drive

next, and vice versa). This device is used

to achieve the repeatability. In case of

axis it repeats the position linearly and in

case of spindle it reaches the same angle in

a circle thereby able to produce a thread.

Resolver:

This is the

one of the earlier devices. This is an

analog device. It can be checked with a

scope. Still, it is hard to tell whether it

is OK or not. Best way is to switch it, if

it is suspected. One has to keep an eye for

the bearing in the unit, which tends to go

bad.

Encoder:

This is a

digital device, which is used as a

positional feedback device. It has a

photocell and three receiving cells, one for

home position and two for incremental

position. This can measured with a scope.

Look for two square waves. One has to keep

an eye for the bearing in the unit, which

tends to go bad.

Pulse Coder:

This is

very similar in construction to the Encoder.

This is used to provide both velocity and

positional feedback. The output from this

unit can be configured to go to drive first

and control next or vice versa. When there

is problem, any one of the three areas,

drive, control or pulse coder could be

causing it and it is difficult to say which

one.

Scale:

Though

there are a few kinds of scales available,

Linear glass scale is the widely used one.

The scale has to be kept clean. It has a

reader moving on it linearly. This has a

photocell and three receiving cells, exactly

as in the case of encoder. There is home

pulse every so often. Also there is a unit

inside the scale, which can be moved to

assign a home position pulse. The output of

the head is connected to a Preamp.

Pre Amp:

A Preamp is

used to amplify the signals, which are

generated in the head of the scale. Normally

one would find more than one of these units.

If one unit is suspected it is very easy to

swap it. This is the easiest way to

troubleshoot it.

|