|

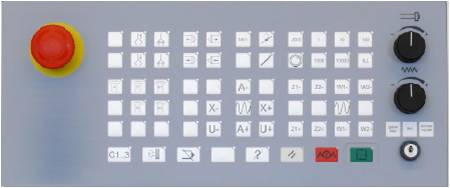

New

control with 2 year warranty

.JPG)

Are you a job shop owner wanting to compete

with a million dollar machine. At

$20 an hour your pay off of the machine is

less than 4 years. This

machine price and quality can help you quote

for $60/hour and still leave a healthy

margin. If you are running three shifts your

pay off should be less than one year. If you

are charging $100/ hour your and running 3

shifts you should be able to pay off

in less than a year.

The machine effectively can be sold after 10

years for a 100K. Where as you write off on

this machine is only 50K.

If you buy a million Dollar machine, after

10 years it will be worth 150K. Your write

off would be 800K plus

You can compete with your competitor for

1/10th of a price compared to someone with

a new machine.

Studer parts are available for a long time.

I have bought parts for a machine made in

1940s. Fanuc parts are available for a long

time. I have bought parts for Fanuc 2000 control

which was made in 1960s.

If you have one of these machines with a

Siemens 3G control, yes it can be rebuilt

for 150K. Ball screws can be changed for

20K. Effectively you have a machine for 170K

like new.

The logic is written by me who has done

service for 32 Years you will have no

service call for PLC alarms. Num tech

support is free for drives and controls.

Learning programming is a one day job.

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

-

Machine is stripped down and being

rebuilt. Loading pictures for you to see

the rebuild.

-

No maintenance for a few years

-

State of art Num control.

-

One step backup.

-

Free installed Ladder tools to

troubleshoot the machine.

-

Remote troubleshooting is easy.

-

Team Viewer compatible.

-

If you are training / helping an

operator run a machine you can doing it from your desk or home.

-

If you are a

supervisor and want to watch all machines run, you can do that as well.

-

FINANCING AVAILABLE FROM US BANK

-

SIMPLE ONE PAGE APPLICATION

-

TERMS FROM 12 months to 60 months

-

Training available

-

Turnkey available

-

Control:

NUM

-

Location: Dayton Ohio, USA

-

Origin: Switzerland

NUM controls are top of the line control

made in Switzerland. NUM technology is

advanced in terms of architecture, servo

design, and being able to do PICO level

positional feedback. NUM is big enough to be

able to support any specialized project, yet

small enough to service and support all

issues locally. Their application support is

unparalleled. You see NUM control on high

end machines like tool cutter grinder and

machine, which make positional control

devices like scale.

You need super precision technology to do

cutting tools and nano level precision

positional control systems. To manufacture a

nano precision product, the control should

be able to process PICO level processing. We

chose NUM because we cannot go wrong with

high precision control. The distributed I/O

and high density makes it easy to wire up a

machine. Front end is an open architecture,

remote troubleshooting is easy, and Team

Viewer is compatible. If you are training /

helping an operator run a machine, you can

do it from your desk or home.

If you are a supervisor and want to watch

all machines run, you can do that as well.

We use the nPad hand held pendant. It is

handy to setup grinding process using the

pendant. The precision of the control,

local support, and remote features makes

this control a retrofitter's dream. Easiness

of the control and the flexibility makes it

versatile for the end user to program.

Call

*Ven at 937 609 5387 or Ven@cnconestop.com

|