|

What is a CNC Retrofit?

Changing the control of a

CNC machine is a CNC retrofit. The

updated control helps with latest features

as well availability of spare parts.

What is a full control retrofit?

A full control retrofit included drives and controls.

New electrical panel. Check spindle drives / dresser drives are included.

it. Operator training and application training ar e

included. Manuals and electrical prints. Macros are included for your

programs. e

included. Manuals and electrical prints. Macros are included for your

programs.

When would a machine warrant

a CNC retrofit?

If the iron is worth 100,000

USD, then the machine is worth retrofitting.

As a thumb rule, if the new replacement

machine costs 175,000 USD or above it is

worth looking into.

What NOT to do, during the

process?

a) Make sure the outfit has

done this before and has been in business

for a long time. b) Go with standard

controls. PC based controls has a lot risks

in continued support for the next 20 years.

c) Get all the manuals. d) Get all the back

ups made including any SOURCE code and

Ladder logic. e) MAKE SURE THERE THE

PROGRAMMING/ MACROS ARE INCLUDED. In

grinding machine this is approximately 25K.

Would CNC onestop do

retrofits?

Yes we do retrofits of

special machines where the iron is worth at

least 100K or more. We have moved up on

the value chain and we do not do any low end retrofit. They are low margin business and

we would not be able to do justice to the

customer when it comes to support. We

support one customer at a time. We strive

for 100% customer satisfaction. Low end

retrofits do not fit our business plan.

Does that mean it is not

worth doing retrofit which are somewhat of a

low cost?

Not really. You can do the

retrofit as long as you can cover all the

bases and it makes financial sense to you

What control does CNC

Onestop retrofit.

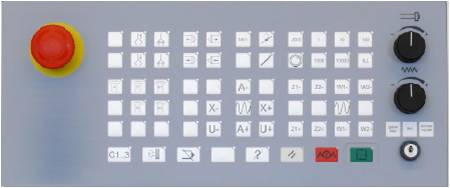

NUM controls are top of the line control made in Switzerland. NUM technology

is advanced in terms of architecture, servo design, and being able to do

PICO level positional feedback. NUM is big enough to be able to support any

specialized project, yet small enough to service and support all issues

locally. Their application support is unparalleled. You see NUM control on

high end machines like tool cutter grinder and machine, which make

positional control devices like scale.

You need super precision technology to do cutting tools and nano level

precision positional control systems. To manufacture a nano precision

product, the control should be able to process PICO level processing. We

chose NUM because we cannot go wrong with high precision control. The

distributed I/O and high density makes it easy to wire up a machine. Front

end is an open architecture, remote troubleshooting is easy, and Team Viewer

is compatible. If you are training / helping an operator run a machine, you

can do it from your desk or home.

If you are a supervisor and want to watch all machines run, you can do that

as well.

We use the nPad hand held pendant. It is handy to setup grinding process

using the pendant. The precision of the control, local support, and remote

features makes this control a retrofitter's dream. Easiness of the control

and the flexibility makes it versatile for the end user to program.

DRIVE RETROFIT

When to

retrofit a drive?

If your

drive is old and cannot get

parts or If you

cannot find a motor, If you cannot find the

Feedback device Example Encoder, Resolver or tach.

What

info is needed for a Drive retrofit?

1)

Drive is A/c or D/c. 2) KW or HP rating of

the drive 3) What is the input voltage 110

or 220 3Ph or 440V a/c 4) Does the motor has

a feedback 5) What type of feedback does it

have Example Encoder, Resolver or tach. 6)

Spindle drive or a servo drive 7) What are

the inputs used (Like drive enable, estop..)

8) What are the outputs (Like Drive ready,

Alarm, Zero speed etc)

What

are the phases and how long does it take?

1)

Planning phase 3 hours 2) Research phase on

matching a drive 2 to 4 hours 3) Drawing

prints for the new drive - 2 hours 4) Wiring

phase - 3 to 12 hours 5) Start up - 3 to 8

hours 6) Run off - 2  to 8 hours Total

time of 30 to 60 hours to 8 hours Total

time of 30 to 60 hours

How

easy is it to retrofit a drive?

It is

not difficult. But is takes dedicated

planning and testing.

Does

ever a drive retrofit fail?

Never.

There may always be some small bugs. But

they are not impossible to fix.

Has CNC

Onestop Inc. done Drive retrofit?

We have

carried out more than 100 drive retrofits.

What

are the different types of drives that has

been used in the Retrofits?

Control Techniques, Yasakawa, Fuji,

Mitsubishi, Vacan, Yasakawa, Kollemorgen,

Vickers, Siemens, Baldor and many more..

What is the qualification of your

personnel?

We have

engineers in staff who have Mater's

degree in Electronics. Ven has specialized

in PWM control of drives. If you have drive

problem we can help you, guaranteed.

We can do the wiring. Can you help us

with the planning phase and identifying the

drive?

Absolutely. The planning and identifying

phase would take us about 8 to 12

hours.

For

Drive

Retrofit

contact

Ven Swaminathan - 937 427 5847 -

ven@cnconestop.com

|